USB2.0 USB Pendrive

USB 2.0 flash drives are currently the mainstream style. Almost all USB drives can come with a USB 2.0 interface. While USB 2.0 interfaces have slower transfer and read/write speeds compared to USB 3.0, they are cheaper in price, making them the most cost-effective USB drives available.

USB 2.0 Flash Drive Styles

USB 2.0 remains the mainstream interface in the flash drive market, offering stable performance, wide compatibility, and cost-effective storage solutions. In traditional USB drive customization and mass production, USB 2.0 is still the most in-demand option. Unless otherwise specified, all our customized USB drives are produced with USB 2.0 as the default standard.

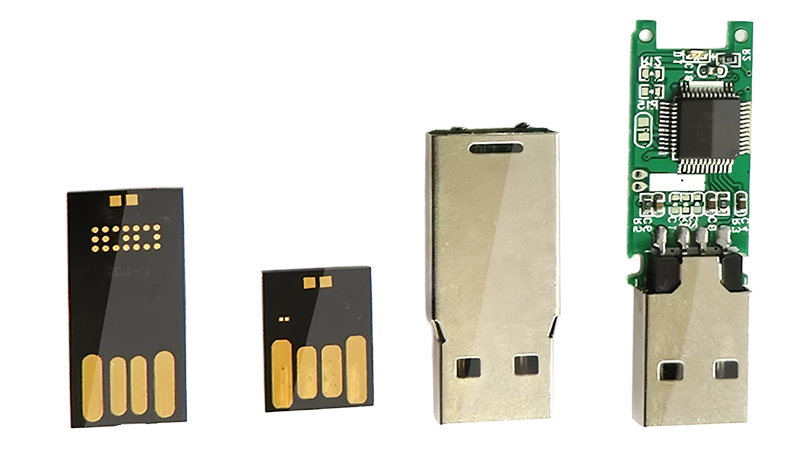

USB2.0 thumb drive chip

USB 2.0 remains the mainstream interface in the flash drive market, offering stable performance, wide compatibility, and cost-effective storage solutions. In traditional USB drive customization and mass production, USB 2.0 is still the most in-demand option. Unless otherwise specified, all our customized USB drives are produced with USB 2.0 as the default standard.

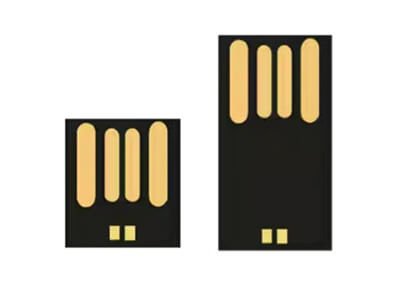

UDP USB 2.0 Chip

UDP FLASH Chips come with a USB 2.0 interface,ensuring fast and efficient data transfer

USB2.0 TYPE-C UDP Mini

it is a compact,cost-effective host controller and flash memory solution tailored for USB Type-C devices

OTG Chip With Type-c

it is an advanced dual-role host controller solution designed for versatile USB Type-C storage devices

USB 2.0 Chips Type-A

The USB2.0 PCBA is an advanced modular assembly combining a high-speed USB 2.0 host controller

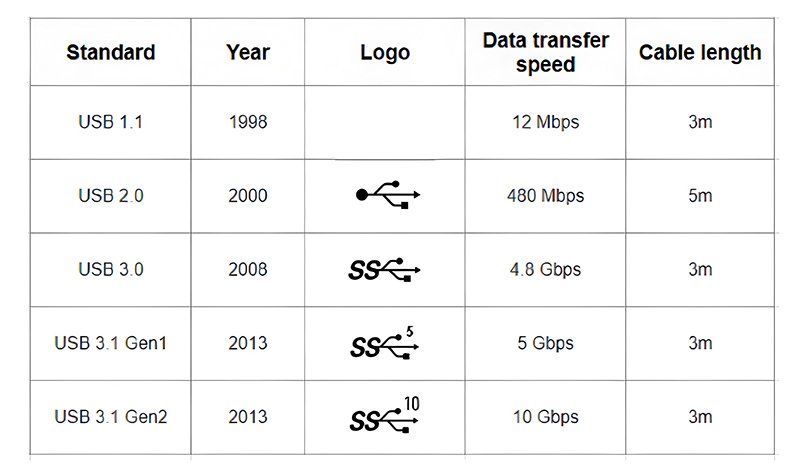

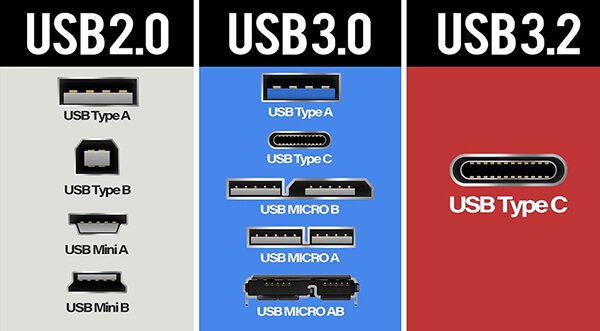

Different USB standards for type A connection

USB-A Standards

Different types of ports are built into different electronic devices. Among the most used are USB-A, USB-B, and type C. In the proAV industry, USB-A is the dominant connection type and it is built into almost all KVM extenders and USB extenders. The below chart shows the property of different standards for USB-A connection.

USB 3.0 is more often seen with a type-C connection or a USB-A to type-C cable. It may be a future trend as it’s more powerful in speed rate and it is able to transmit both video and USB data.

The main advantages of USB 2.0 flash drives lie in their low cost, high compatibility, and stability. They are more suitable for scenarios where there is no high demand for transfer speed, cost-effectiveness is a priority, or adaptation to older devices and bulk customization are required.

Lower price

USB 2.0 technology is mature with simple production processes, making its manufacturing cost much lower than that of USB 3.0/3.1 flash drives.

Strong compatibility

USB 2.0 is compatible with almost all devices that support USB interfaces, so there's no need to worry about device interface mismatches.

High stability

Its transmission protocol is simple and mature, resulting in greater stability in daily use (such as small file copying, system booting, etc.).

Bulk customization

USB 2.0 flash drives are used for bulk customization (such as gift USB drives, promotional giveaways, corporate promotional USB drives, etc.).

Customer cases of USB2.0 Flash drives

Tooth-shaped USB drive

Toothpaste-shaped USB drive

Ultra USB 3.0 Card Flash Drive

PVC letter-molded USB drive

PVC car key-shaped USB drive

Luggage-shaped USB drive

Cartoon construction worker-shaped USB drive

Brush-shaped USB drive

Metal flip USB drive

Metal plug-in USB drive

FAQ About USB2.O Flash drives

1. Can I print a logo when customizing USB 2.0 flash drives? What printing methods are available?

Yes, logo customization is supported. Common methods include silk screen printing, full-color printing, laser engraving, epoxy dome, and embossed logos. The method depends on the material of the drive, such as PVC rubber, metal, or plastic.

2. What’s the MOQ for bulk USB 2.0 drives? How long is the lead time?

The typical MOQ is 100 units. Standard lead time is around 7–12 working days depending on the customization details. If custom mold development is required, the production time may be longer and should be confirmed case by case.

3.How can I choose a reliable USB flash drive manufacturer?

Look for manufacturers with their own factory, complete production capabilities (like SMT, assembly, and testing), ability to provide samples, and years of export experience with good client feedback. Also, make sure they offer formal contracts, quality guarantees, and after-sales support.

4. What capacities are available for USB 2.0 flash drives? Can I preload data onto them?

Common capacities include 1GB, 2GB, 4GB, 8GB, 16GB, and 32GB. Preloading files such as brochures, videos, or password-protected documents is supported. Auto-run features may be available depending on the operating system.

5. What should I pay attention to when customizing USB 2.0 drives?

Confirm the chip brand (e.g., Samsung, Toshiba), interface type, color options, logo file format, and whether a sample is needed before mass production. Also consider warranty terms and certifications like CE, RoHS, or FCC if required.