Factory specialized in personalized key rings

- BSCI and ISO9001 certified factory

- Specialized in small and medium batch production

- We accept rush orders and free design

Hot keychain category

Our factory keychains are classified according to material, process and usage, among which 3D pvc material is our most customized style.

Key ring customization process

We offer a complete chain customization service from design to delivery, covering more than 10 materials, such as metal, leather, silicone, etc., and supporting customized requirements, such as shape molding, logo engraving, IP co-branding, etc.

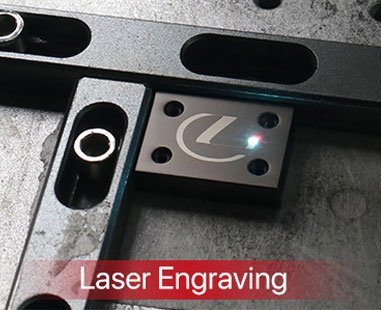

laser engraving

A high-energy laser beam creates a permanent mark on the surface of the material, combining precision, efficiency and environmental friendliness.

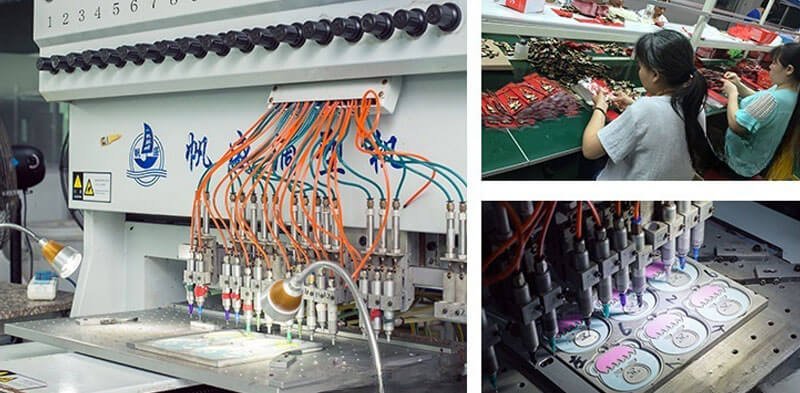

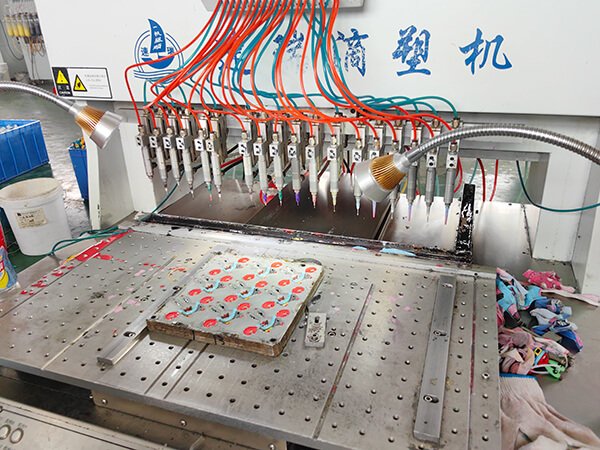

dispense glue

Formation of complex patterns or three-dimensional structures by precisely controlling the filling of molds with colloidal materials.

epoxy sticker

A high-energy laser beam creates a permanent mark on the surface of the material, combining precision, efficiency and environmental friendliness.

Hot Press

A process in which pressure is applied to the surface of the skin by means of a mold to form a concave or convex texture or pattern.

UV Printing

UV color printing keychain is a kind of printing pattern on the surface of acrylic, PVC and other materials by UV curing ink.

Key Ring Factory Service

The keychain factory offers full customization service from creative design to mass production, the products are suitable for brand promotion, tournament commemoration, corporate gifts and other scenarios, supports OEM/ODM mode, the minimum order quantity is as low as 50pcs.

Small test order

Support small batch trial production from 50 pieces, free sampling optimization service, you can check the production progress in real time, and the trial order delivery can be completed in 7 working days, which reduces the cost of trial and error in the market.

Design services

Provide keychain appearance, structure, IP co-branding and other complete case design, support in the form of open mold (heart, cartoon, custom brand logo), free to provide 3 versions of the design scheme and 3D preview effect diagram

Tailor-made production

It adopts more than 10 materials, such as PVC/wood/metal, and is equipped with a fully automatic die-casting line and 6 quality control processes (including salt spray test/tensile test), allowing for customized packaging with an annual production capacity of more than 3 million pieces.

Key ring manufacturing process

The key rings are produced through design, mold creation, injection of materials such as PVC, painting, adhesive application, assembly, quality control and packaging.

1、Selection of materials

2、Creation of molds

3、Colorization of figures for key rings.

4、Application of adhesive

5、Finished skulls

The advantages of our factory

We are a professional PVC keychain customization factory. We have high quality, eco-friendly and safe materials. We own precision molds to ensure quality and flawless finish. In addition, we offer flexible customization according to your needs, with unique and colorful designs.

Environmentally friendly materials

Phthalate-free, heavy metal-free, leucocyanin-free, no risk of allergies on direct contact

Certification Report

Inspection and certification by professional bodies, rigorous quality control of key fobs

High precision mold

High quality mold, no rough edges, vibrant color without chromatic differences.

Custom color

Pantone number matching, free effect design, sample in 3 days.

- PVC key ring quality inspection

1. Appearance inspection: Observe if the surface is smooth without burrs, bubbles or impurities, the color is uniform without overflows and the edges are free of burrs;

2. Physical evidence: bending the key ring to check if it is easy to break, and tensile test to ensure the firmness of the hook;

3. Smell and material: no pungent chemical odor, soft material and no mixed colors or impurities;

4. Functional verification: check the clarity of the printing/engraving patterns;

5. Packaging standards: absence of stains on the finished product, sealed and damage-proof packaging, complete labeling information.

Our customers

14 years of factory experience, producing custom keychains for thousands of customers, with a variety of styles and colors, from design to production and shipping.

Certifications

Our commitment to quality is backed by international certifications.

BSCI

Corporate Social Compliance Initiative

iso9001

Quality Management System

CE

CONFORMITE EUROPEENNE

Rohs

Restriction of Hazardous Substances